Turning to forest for water resistance

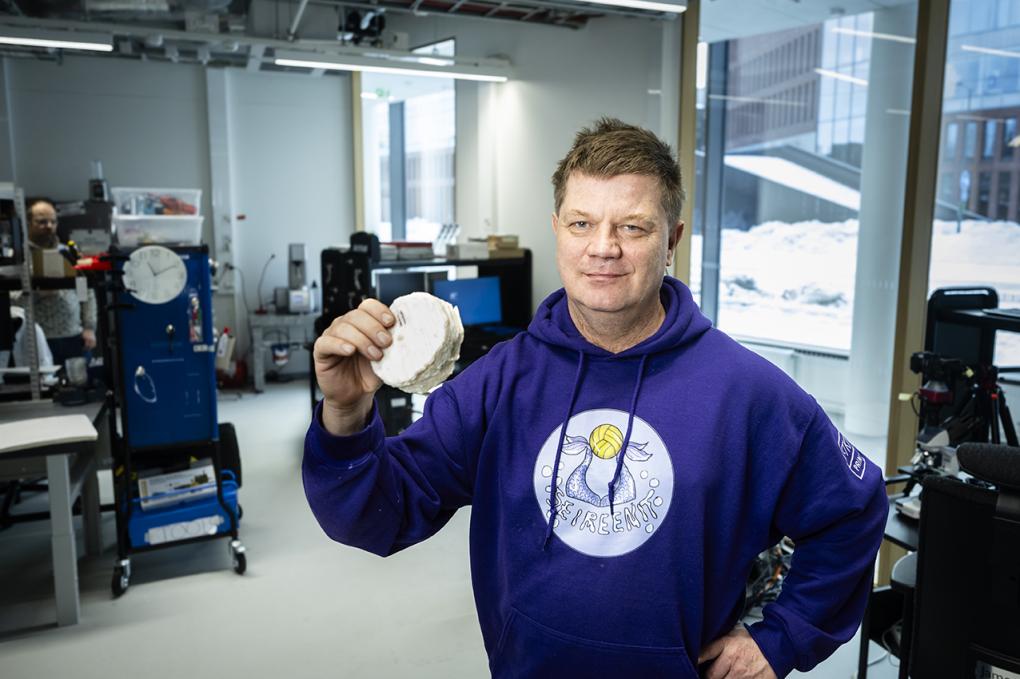

When replacing plastic with wood, water resistance becomes an issue. Mikko Alava is looking for an answer from lignin found in wood and sometimes asks artificial intelligence for advice.

All over the world, people are competing to find solutions to replace plastic products with wood-based alternatives.

As a material, plastic is functional, durable, practical, and cheap. The problem lies in the fact that plastic is made from crude oil, so it sustains our dependence on fossil fuels.

“There is an immense amount of wood in Finland, and it could be processed further than just into paper and cardboard,” says Mikko Alava, professor of physics at Aalto University.

When it comes to water resistance, wood pales in comparison with plastic. Anyone who’s ever used disposable tableware outdoors has noticed how wood-based plates and cups get wet.

A thin plastic coating has to be added to paper coffee cups, resulting in the material no longer being fossil-free; and even then, a paper cup will eventually get soggy.

Thus, the key question is to develop a water-resistant wood-based material to replace plastic. Alava and his colleagues aim to find a solution with the help of lignin.

Lignin constitutes 30% of the mass of wood, and it’s a polymer, a bundle composed of small molecules. Lignin is formed by the coupling of three phenylpropane units, and its structure varies individually.

Lignin is easily available; initially, lignin comprises up to a half of the black liquor of a pulp digester. However, in terms of paper and cardboard, lignin is a harmful substance. In pulp manufacturing, it is discarded, and eventually it will be burnt to generate energy.

“In the future, lignin might be more valuable as an alternative for plastic than as fuel.”

AI to the rescue

Lignin is water-repellent. It forms vascular tissue in trees and other vascular plants, enabling the conduction of water and thus sustaining the life of the plant.

With the help of lignin, a tree can control its water transportation and doesn’t get soaked. This means that in order to replace plastic with wood-based materials, lignin must be organised as neatly as it is within wood.

“Our goal is to break down the wood and then rebuild it. The fibres are used to make foam, and lignin is added to this foam to make it water-resistant.”

On a general level, the recipe is simple: make foam out of cellulose fibres, then throw in lignin, stir and mix, and let dry – and you’ll have an alternative for plastic.

Alava and his colleagues, researchers Juha Koivisto and Tero Mäkinen and two graduate students are still unsure as to what the best structure for this wood-based material is and what process should be used to produce it in a way that makes the material water-repellent. They are trying different kinds of mixing ratios and mixing and heating methods, then testing the properties of the material.

There are endless opportunities, so they’ve turned to artificial intelligence for help.

“We can give artificial intelligence all the information we have gathered so far and ask what should or shouldn’t be tried next. This way, we can skip 90% of the tests and just conduct the ones artificial intelligence deems relevant,” Alava says.

A successful yet soggy substitute

The idea of a water-repellent wood product is a successor to Foamwood, a process that Alava and his group created to make lightweight and solid foam from forest materials as a substitute for expanded polystyrene.

The foam isn’t water-resistant, but it’s been useful in dry environments, such as replacing bubble wrap in parcels. Startup company Woamy is looking to turn it into a commercial success.

“Being able to send products without plastic is a competitive advantage for various companies,” says Alava.

Packaging for ready meals and restaurants

Alava is confident that his team will find a recipe for a water-resistant alternative for plastic.

“Our efforts will probably succeed, and we’ll also come up with something unexpected, as is often the case in research.”

Sometimes an invention can also turn a profit, but this remains to be seen.

Alava and his colleagues aren’t looking for a perfect solution. When each and every lignin molecule is different, it can be difficult or even impossible to develop an industrial process for products that are expected to remain 100% waterproof for decades. Hence, we’re unlikely to see a wood-based Styrofoam in frost insulation; a wood-based packaging material for ready meals and restaurants is a much more likely outcome.

“As long as the product is water-resistant enough and easy to recycle after use, it’s good,” Alava concludes.